Test benches for galvanic cells

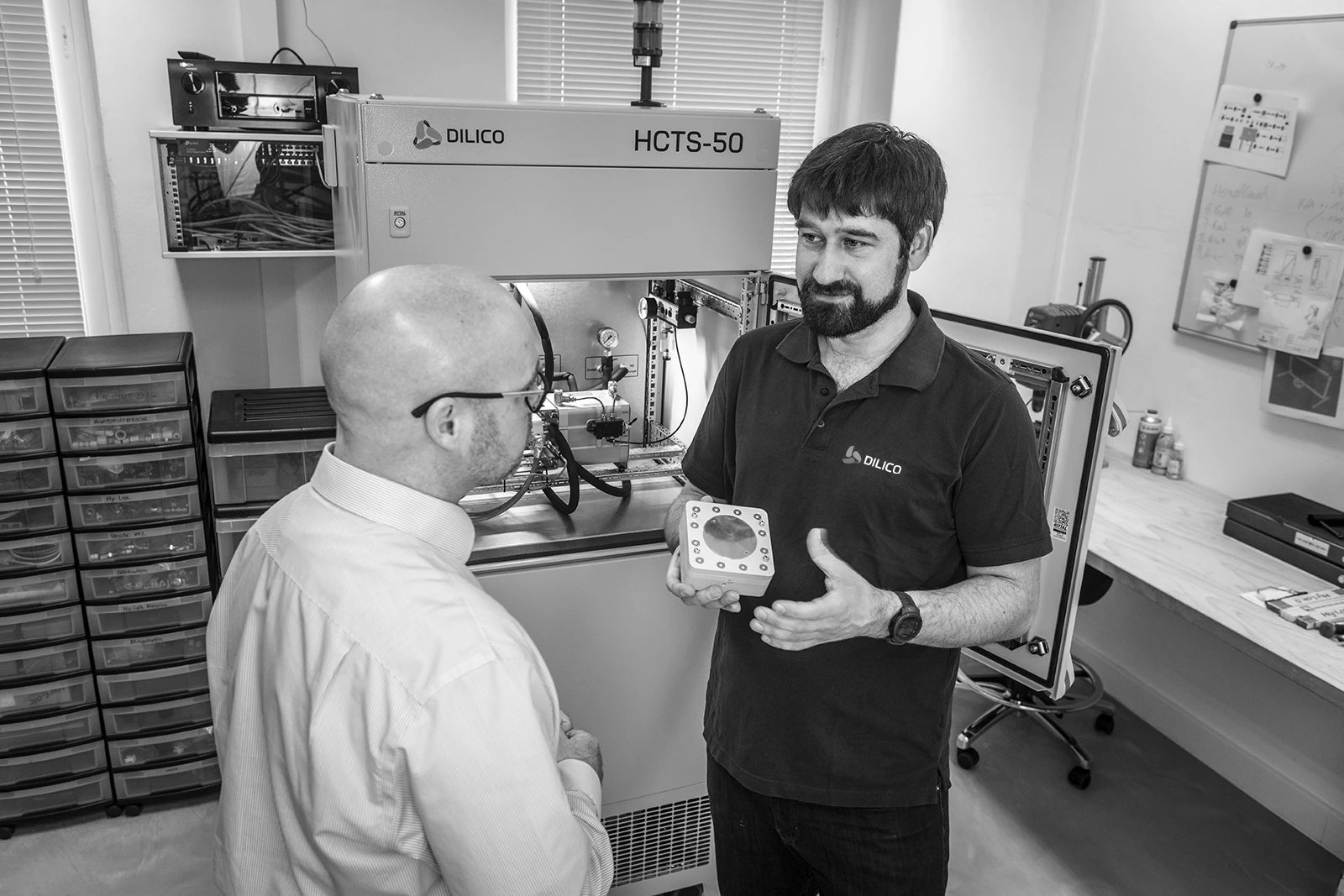

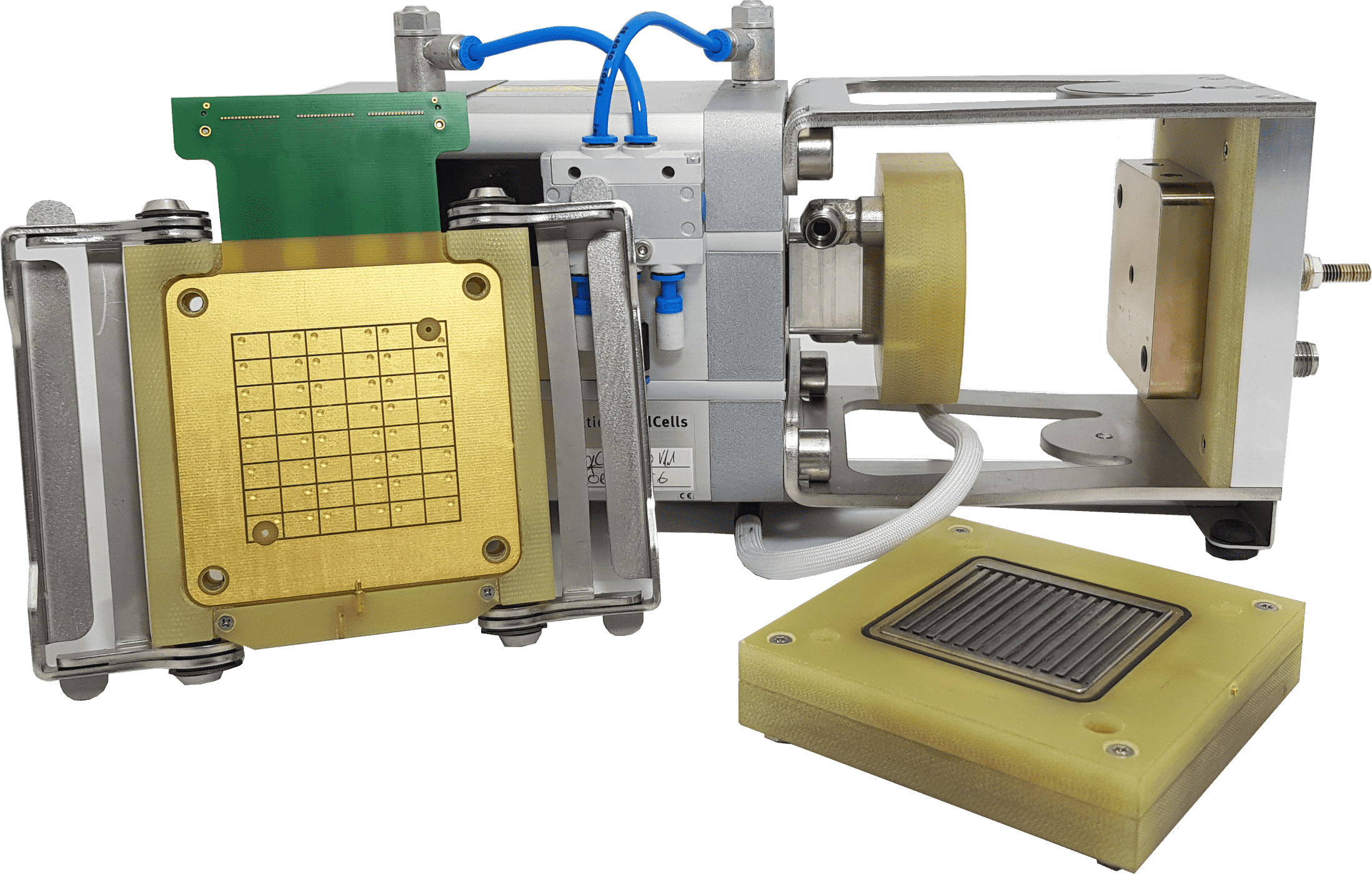

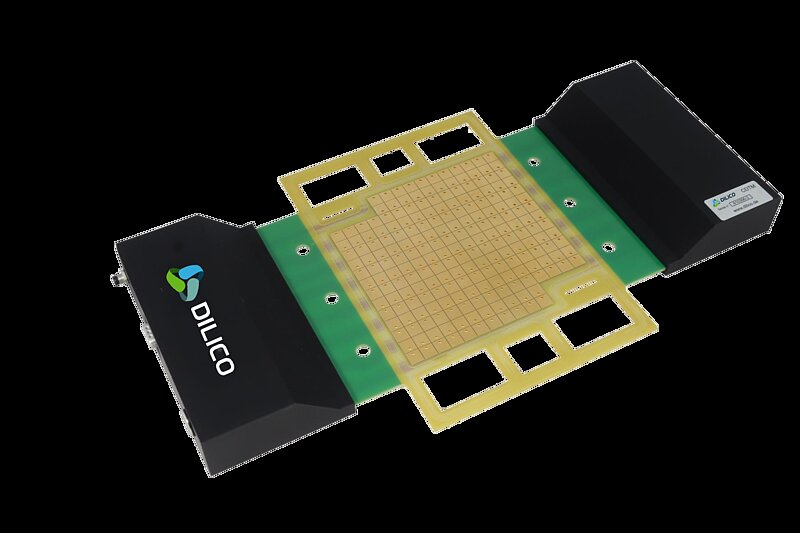

The technology of the fuel cell is still new in today's application areas and requires test benches for continuous improvement, with which functionalities and operating strategies can be tested. Each of the different technologies of fuel cells and electrolyzers requires an adapted test environment. In the following, we will discuss the different types and their applications. Furthermore, we inform about the use of DiLiCo engineering's measurement systems in the context of test benches.